The commissioning of a biogas plant

The commissioning of a biogas plant is a multi-stage process that requires precision, and its successful completion ensures the efficient and safe operation of the plant.

Photo: Lauri Penninkangas tests the reactor’s gas space pressure

Before starting the actual biogas process, all equipment in the biogas plant-sensors, meters, pumps, and hundreds of other components-are tested individually. Testing and inspections are essential steps in commissioning a biogas plant to ensure efficient and safe operation. IO tests verify that all inputs and outputs function correctly, for example, that pumps rotate in the right direction. Only after confirming that all systems work properly can the biogas process itself begin.

The commissioning of Demeca’s biogas plants is overseen by automation designer, Demeca founder and partner, Lauri Penninkangas:

“Every phase of the commissioning is carried out with care-pressure tests, maintenance checks, and inspections by third parties and authorities ensure the plant meets all technical and legal requirements and is safe to operate,” says Lauri.

Start-up of the Biogas Process – Planning Ensures Efficiency

The start-up of the biogas process follows a carefully prepared plan once commissioning is complete. At the time of the interview, Lauri and Demeca’s maintenance team were commissioning the biogas plant complex at the Pyhäntä circular economy park. The process begins by filling the first reactor to about halfway to start biogas production quickly and with minimal energy. According to Lauri, agricultural slurries are usually used at the start to provide a stable base for bacterial activity. If needed, inoculum-ready-made bacterial mass-can also be used to initiate the process.

Once the biogas process is running, feedstocks are gradually added according to the start-up plan until full process capacity is reached. Throughout the process, gas quality-especially methane concentration-is closely monitored. When methane levels are high enough, gas-consuming equipment, such as burners for process heat, can be brought online.

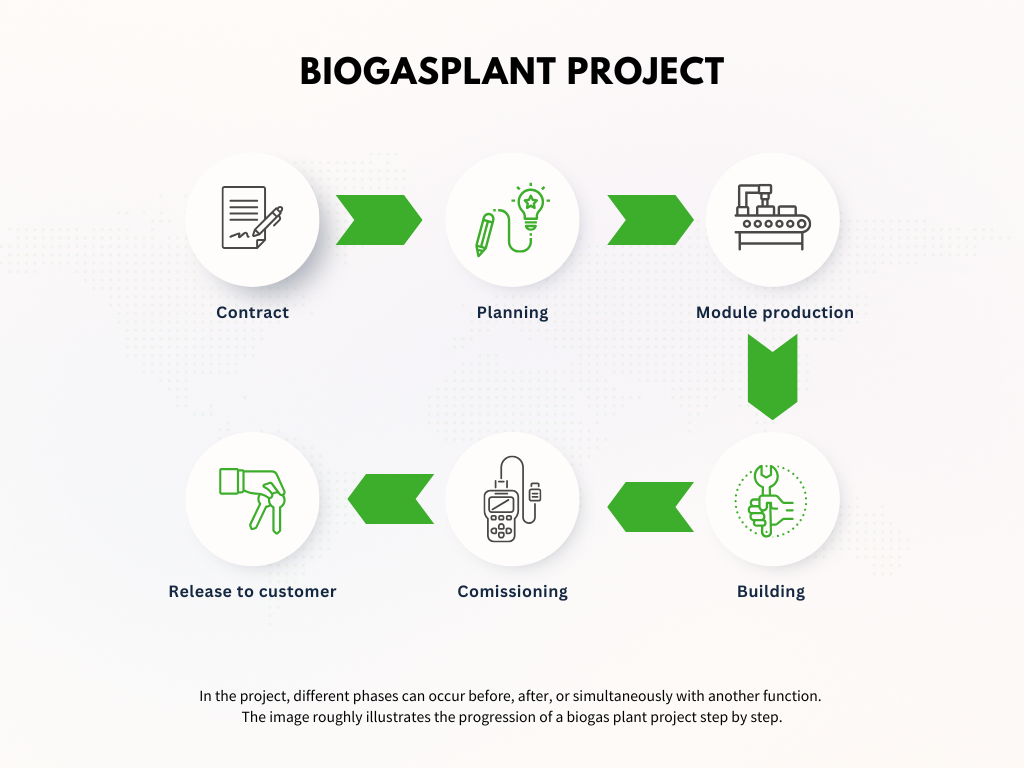

Photo: The commissioning of the biogas plant is the phase after construction and before the handover of the plant

Collaboration and Training – Smooth Handover to the Customer

During commissioning, customers are actively involved in the process. The experienced commissioning staff train customers in the operation and maintenance of the plant. Demeca handles commissioning and initial operation, so customers do not need to spend time on technical details-system operation and checks are managed professionally. Commissioning typically lasts from a few weeks to a few months, after which the plant is handed over to the customer. Operation and maintenance continue after handover under a maintenance agreement.

Smart Solutions Ensure Operation and Safety

We provide smart solutions for biogas production and upgrading. Commissioning ensures the functionality of our smart solutions before the biogas process begins and before the plant is handed over. For example, temperature sensors installed in the pump stators act as dry-run protection. If the slurry does not flow as it should, the temperature rises, and the sensor triggers an alarm, preventing equipment damage and process interruptions. Such details are part of the comprehensive approach that ensures safe and efficient operation of the biogas plant.

Photo: Lauri is testing the operation of temperature sensors at the biogas plant in the Pyhäntä Circular Economy Park

Commissioning a biogas plant is a process that requires careful planning and expert execution. Demeca’s extensive experience and expertise guarantee high-quality commissioning and training for an energy-efficient biogas plant process. When done correctly, quality commissioning gives farms and plant operators the confidence to continue safe operation after handover.